Online Self-Service End-To-End Platform. A Great Product Starts With A Great PCB.

The Basics Of Metal Core Pcb Design And Manufacturing Nwes Blog

If you need RF board then consider.

. Metal Core Pcb Design Guidelines In Altium. Start Your Quote Now. Ad Turnkey PRO By Sierra Circuits.

If youd like to use high density need dozens of layers then use multi-layer FR4 PCB. If want good heat elimination then metal core PCB will be a good idea. The mechanical structure is made with insulating materials laminated between layers of conductive material.

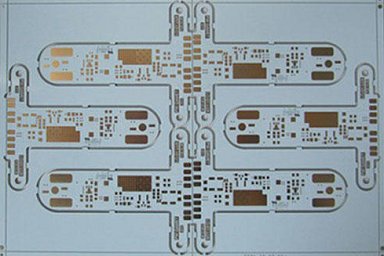

PCB design basis and design. This metal core PCB comes with over two layers. Manufacturing Printed Circuit Boards Since 1985.

A prototype of a metal core printed circuit board is a lot like a typical PCB. Metal Core PCB Design Guidelines. 1500 New Customer Introductory Credit.

However its more sophisticated and complex in its design. Hence the structure looks like the FR4 multi-layers. Or you can make the circuit board single-sided leaving the back of the metal core exposed.

Multi-Layer Metal Core PCB. Online Self-Service End-To-End Platform. 1A double-sided metal core PCB comes with a metal core between two of the boards conductor layers.

Get Your PCB In 5 Days. These types of PCBs are provided with 2 layers of copper material which are placed on either side of the metal part. The most common is an aluminum.

PCB Production Lead Time. Double-Sided Metal Core PCB. For this metal core PCB to.

Get Your PCB In 5 Days. The final figure of the circuit board should. Just like any other PCB you need to follow some basic DFM guidelines for your particular board if you want to ensure a successful fabrication run.

The IPC-2221 is a general standard that envelops every aspect of the PCB design. Metal core can be Aluminum or Aluminium or. Ad Turnkey PRO By Sierra Circuits.

Metal Core PCB Capability. Also this standard considers how conductor clearance and PDN bus layouts should be on the PCB. Printed Circuit Board PCB manufacturers typically follow three types of stackups for boards they will assemble with high.

Metal core PCBs have a distinctive thickness compared to other boards. Start Your Quote Now. The metal core of the thermal PCB can be aluminum aluminum core PCB copper copper core PCB or a heavy copper PCB or a mixture of special alloys.

High-Density Interconnection HDI PCB design guidelines. METAL CORE PCB MCPCB A metal core printed circuit board MCPCB also known as thermal PCB incorporates a metal material as its base as opposed to the traditional FR4 for the heat. A Great Product Starts With A Great PCB.

The MCPCB or metal core PCBs are manufactured around epoxy resin due to its adhesive capacity. Get Your Fast Online Quote Now. 2The metal core merges with the conductors via the SMD and vias usually on top or at.

However their design must be optimized before being. DFM for Metal-Core PCBs. 5052 aluminium is the most cost effective base.

Flex PCBs are the go-to choice for manufacturers due to their longevity and ability to absorb shocks and vibrations. It requires a metal base and must adhere to certain guidelines. Metal Core PCB MCPCB or sometimes Thermal PCB is a technology developed to overcome the thermal limitations of the FR-4 material.

Are there Specific Design Considerations for MCPCB. Design Considerations for MCPCB Manufacturing a Cost-Effective Board. 1050 aluminium is used for bendable MCPCB.

When designing a metal core PCB the following are the manufacturing points that need to be paid. On each side the PCB has copper substrate or foil.

How Do Best Metal Core Pcb Manufacturers Develop Mcpcbs Pcbmay

Metal Core Pcb Mcpcb Aluminum Pcb Manufacturing Process News Seasons Electronics Shenzhen Co Ltd

How Do Best Metal Core Pcb Manufacturers Develop Mcpcbs Pcbmay

The Basics Of Metal Core Pcb Design And Manufacturing Nwes Blog

How Do Best Metal Core Pcb Manufacturers Develop Mcpcbs Pcbmay

Detailed Guide On Metal Core Pcb Absolute Electronics Services

0 comments

Post a Comment